GENERATION NEXT FASHIONS LTD

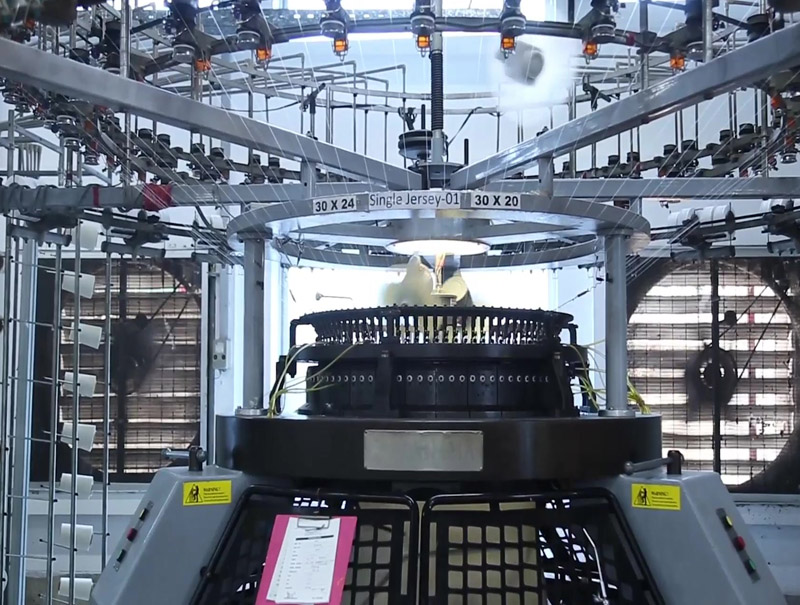

Generation Next Fashions Limited (GNFL) was incorporated in Bangladesh on 19 August 2004 under the Companies Act 1994 with an authorized capital of BDT 500.00 million and a paid up capital of BDT 47.20 million to carry out business of spinning, weaving and manufacturing of various types of readymade garments of international standard and design. At present, the paid up capital of the Company is BDT 4500.00 million and the authorized capital is BDT 5000.00 million. GNFL is a 100% export oriented textile and apparel manufacturing company which started its commercial operation on 30 July 2006.

Read More